Description

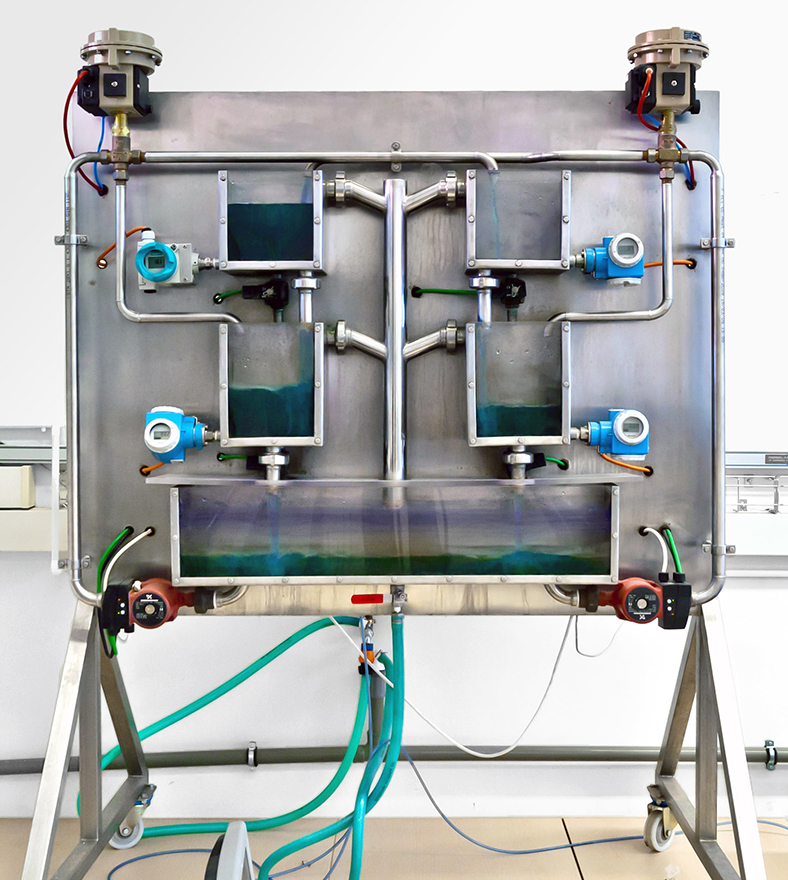

The 4-tanks industrial model implements the control problem proposed by Karl Henrik Johansson (The Quadruple-Tank Process. A multivariable laboratory process with an adjustable zero. IEEE Transaction on Control Systems Technology. 2000). LThe main feature of this scale model is its implementation by industrial elements.

The Automatic Remote Laboratory of (ULE) provides a remote access via internet to this model.

The tanks, pipes, tools, drive and control cabinets are mounted on a stainless steel frame (2mx2m). In this design has been claimed that the operation is quick for both SISO systems to MIMO systems. The drives of the three way valves are pneumatic, while the drives of the pumps have variable frequency. It has 4 solenoid valves, one for each tank, that can disturb the operation. The control cabinet is designed to connect systems based on PLC’s and systems based on DCS’s and it incorporates a number of interlocks and safeguards that ensure the integrity and functionality of the industrial model when they are managed both, locally and remotely.

The design of the models has been made based on the following objectives:

The Automatic Remote Laboratory of (ULE) provides a remote access via internet to this model.

The tanks, pipes, tools, drive and control cabinets are mounted on a stainless steel frame (2mx2m). In this design has been claimed that the operation is quick for both SISO systems to MIMO systems. The drives of the three way valves are pneumatic, while the drives of the pumps have variable frequency. It has 4 solenoid valves, one for each tank, that can disturb the operation. The control cabinet is designed to connect systems based on PLC’s and systems based on DCS’s and it incorporates a number of interlocks and safeguards that ensure the integrity and functionality of the industrial model when they are managed both, locally and remotely.

The design of the models has been made based on the following objectives:

- Portability: Models can be installed in any location, since they have a frame equipped with wheels. All the elements are electric and only require a process fluid outlet, a drain, an Ethernet network outlet and power supply. The fluid in this case is water.

- Flexibility in the control: The design contemplates the possibility of being controlled by PLC, DCS, PC.

- Remote access via internet: For this, they have been provided with wired interlocks that allow safe remote operation.

- Broad spectrum of operation: Models can be configured to establish basic control experiences or advanced multivariable control due to the interactions that can be established between the different regulation variables.

The SUPPRESS Research Group (Supervision, Control and Automation) of the University of León designed, developed and implemented this system. There are also replicas available at the Universities of: UNED (Madrid), Almeria and Oviedo.

Fact Sheet

| TAG | VARIABLE | TYPE | SIGNAL | I/O |

| LT01 | Level D01 | Analog | 4-20 mA | Input |

| LT02 | Level D02 | Analog | 4-20 mA | Input |

| LT03 | Level D03 | Analog | 4-20 mA | Input |

| LT04 | Level D04 | Analog | 4-20 mA | Input |

| LV05 | Level Valve D01-D04 | Analog | 4-20 mA | Output |

| LV06 | Level Valve D02-D03 | Analog | 4-20 mA | Output |

| SZ01 | Pump Converter P01 | Analog | 0-10 Vdc | Output |

| SZ02 | Pump Converter P02 | Analog | 0-10 Vdc | Output |

| ES01 | Confirmation Pump ON P01 | Digital | 24 Vdc | Input |

| ES02 | Confirmation Pump ON P02 | Digital | 24 Vdc | Input |

| ES03 | Pump failure P01 | Digital | 24 Vdc | Input |

| ES04 | Pump failure P02 | Digital | 24 Vdc | Input |

| ES05 | Voltage presence 24 Vdc | Digital | 24 Vdc | Input |

| ES06 | Voltage Presence 220 Vac | Digital | 24 Vdc | Input |

| FY01 | On/Off Pump P01 | Digital | 24 Vdc | Output |

| FY02 | On/Off Pump P02 | Digital | 24 Vdc | Output |

| LY01 | Solenoid Valve D01 | Digital | 24 Vdc | Output |

| LY02 | Solenoid Valve D02 | Digital | 24 Vdc | Output |

| LY03 | Solenoid Valve D03 | Digital | 24 Vdc | Output |

| LY04 | Solenoid Valve D04 | Digital | 24 Vdc | Output |

Pictures Gallery

RECIRCULATION PUMP

UPE 25-40 Grundfos pump equipped with a frequency inverter (Grundfos 40/60) to control it through an analog signal. This pump can operate in two modes: proportional pressure, or constant pressure. It can also be controlled by a signal bus.

©2018 Remote Laboratory of Automatic Control