Descripción

The SUPPRESS Research Group (Supervision, Control and Automation) has designed and built didactic models for process control found in Room E2 of the Technological Building II (University of León). These are test cell control strategies equipped with intelligent industrial instrumentation for measuring and controlling flow, level, pressure and temperature. The remote laboratory of Automatic of the ULE provides a system of remote access, through Internet, to these industrial models.

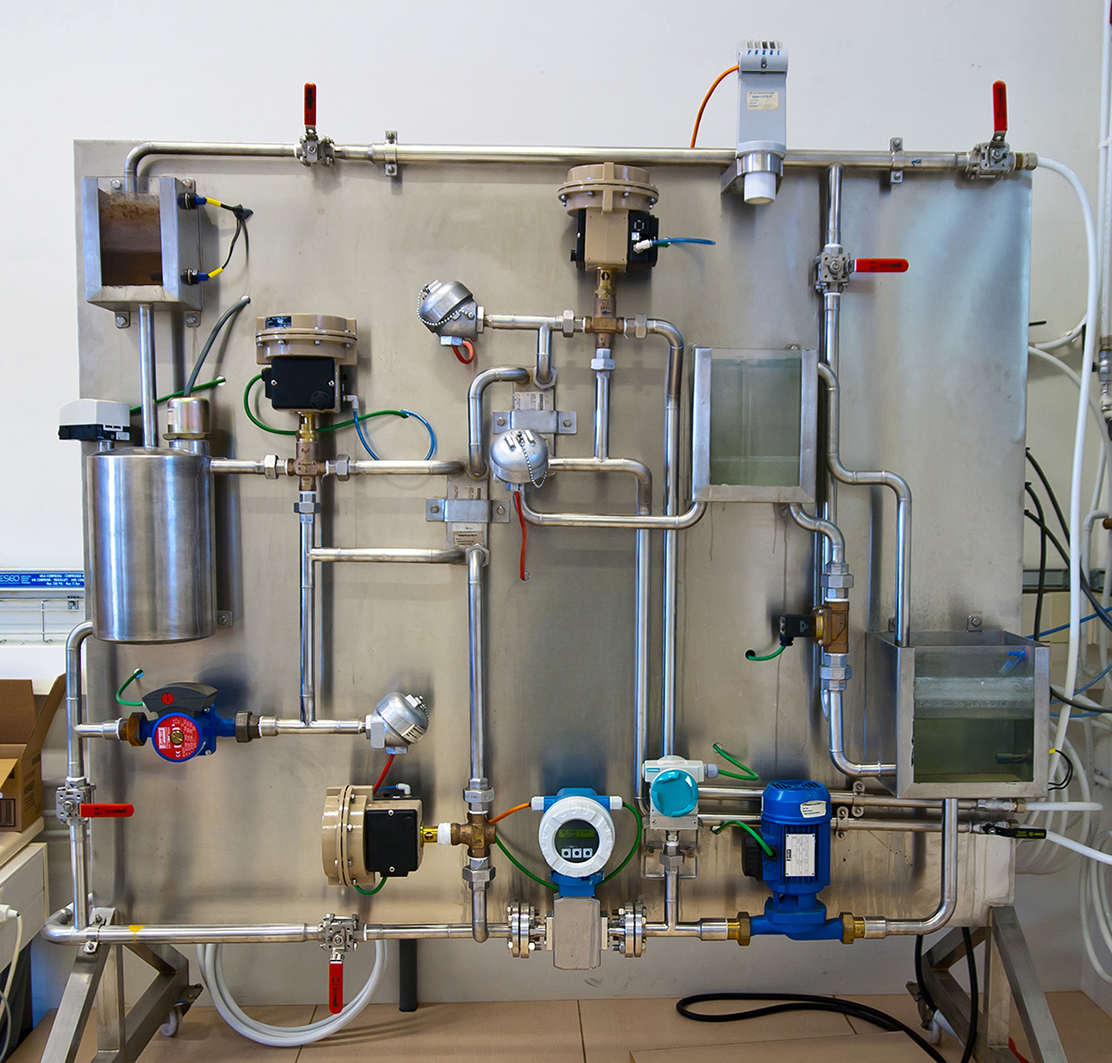

The tanks, pipes, tools, drive and control cabinets are mounted on a stainless steel frame (2mx2m). The design intends that the operation is quick for both SISO and MIMO systems. The drives of all valves are electric, while the drives of the pumps have variable frequency. It has three solenoid valves with variable drives and one of them is on-off. The on-off valve is used to control the rate of processing tank drain, whereas the other 3 valves have variable actuators and are used to regulate the supply of process fluid, to regulate the supply of hot fluid and to regulate the supply from of cold fluid. The model also has two pumps, one to impulse the fluid of the heating tank, which has a frequency inverter to control 3-position through an analog signal, and another to impulse the process fluid, which has a frequency inverter (MicroMaster Vector Siemens) to control the flow.

The tanks, pipes, tools, drive and control cabinets are mounted on a stainless steel frame (2mx2m). The design intends that the operation is quick for both SISO and MIMO systems. The drives of all valves are electric, while the drives of the pumps have variable frequency. It has three solenoid valves with variable drives and one of them is on-off. The on-off valve is used to control the rate of processing tank drain, whereas the other 3 valves have variable actuators and are used to regulate the supply of process fluid, to regulate the supply of hot fluid and to regulate the supply from of cold fluid. The model also has two pumps, one to impulse the fluid of the heating tank, which has a frequency inverter to control 3-position through an analog signal, and another to impulse the process fluid, which has a frequency inverter (MicroMaster Vector Siemens) to control the flow.

Each plant is composed of the following circuits:

- Process circuit: Including pressure, flow, temperature and level variables.

- Hot water circuit: It includes the necessary elements to heat water.

- Cooling circuit: Heat is transferred to the process circuit.

Fact Sheet

- PRESSURE CONTROL

- Sensor: Intelligent Pressure transmitter 4-20mA+HART.

- Actuator: Vectorial frequency inverter acting on centrifugal pump.

- Basic PID control algorithm.

- Three operation modes: MANUAL, AUTO and REMOTE.

- Measured variable: Barg.

- FLOW CONTROL

- Sensor: Intelligent electromagnetic flow transmitter 4-20mA+HART.

- Actuator: Electric 2-way valve with positioner.

- Basic PID control algorithm.

- Three operation modes: MANUAL, AUTO and REMOTE.

- Measured variable: l/h.

- LEVEL CONTROL

- Sensor: Transmisor de nivel ultrasónico inteligente 4-20mA+HART.

- Actuator: 2-way electrovalve.

- Basic PID control algorithm.

- Three operation modes: MANUAL, AUTO and REMOTE.

- Measured variable: %.

- HOT WATER TEMPERATURE CONTROL

- Sensor: Intelligent ultrasonic level transmitter 4-20mA+HART.

- Actuator: Static variable drive for heating resistor.

- Basic PID control algorithm.

- Three operation modes: MANUAL, AUTO and REMOTE.

- Measured variable: ºC.

- PROCESS TEMPERATURE CONTROL

- Sensor: Intelligent temperature transmitter 4-20mA+HART with probe PT-100.

- Actuator: In split-range with two electric 2/3-way valves with positioner.

- Basic PID control algorithm.

- Three operation modes: MANUAL, AUTO and REMOTE.

- Measured variable: ºC.

Pictures Gallery

HOT WATER RECIRCULATION PUMP

SEDICAL TF 110 pump equipped with a three positions frequency inverter to control it with an analogue signal (min-1450 l/min, medio-2000 l/min, max-2100 l/min). This pump is used to archieve homogeneous heating in the fluid that is in the heating tank.

©2022 Remote Laboratory of Automatic Control

©2022 Remote Laboratory of Automatic Control