Description

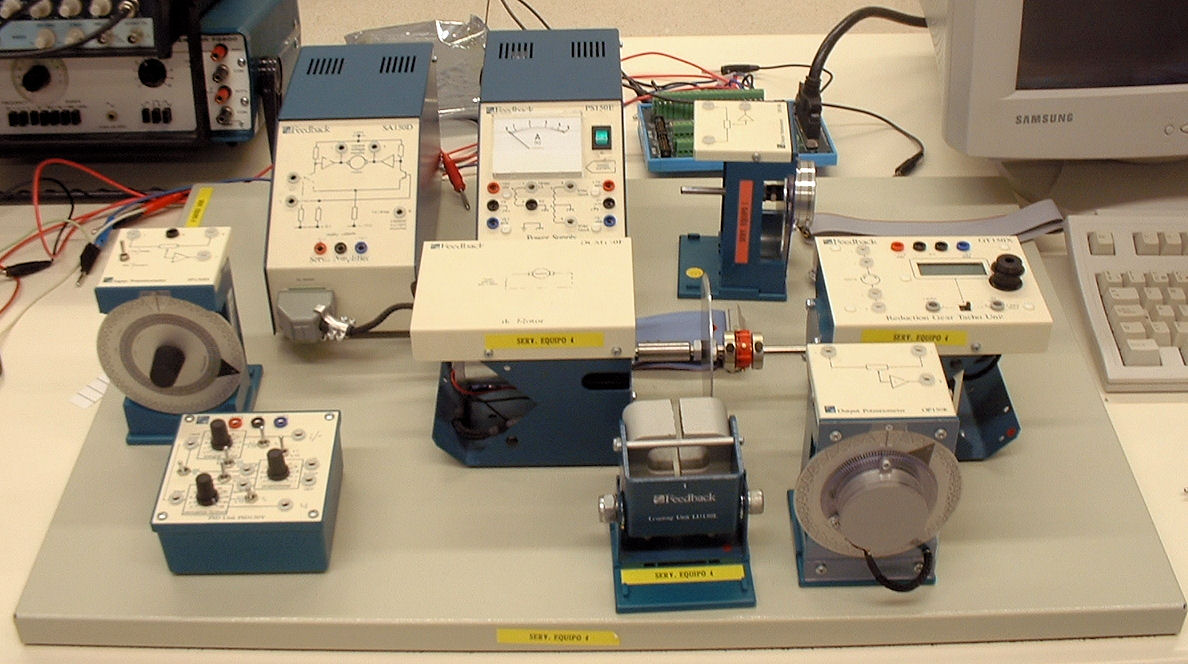

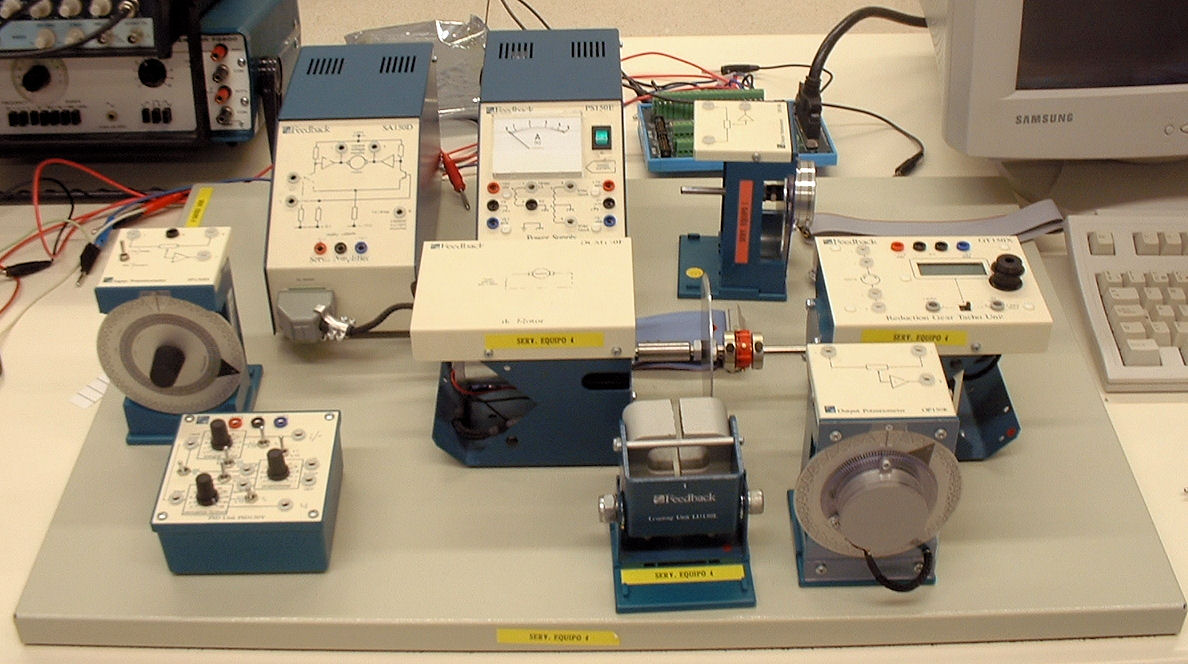

The SUPPRESS group (Supervision, Control and Automation) of the University of León has developed a set of interactive simulations of the different modules of the Feedback-MS150 equipment, a laboratory equipment widely used for the study of control methods with electric motors.

Also, a remote access through the Internet has been implemented to the equipment. A registered user can identify the system from real data of position and velocity of the drive shaft in open-loop, tune a PID, analyze its behavior using a webcam and the historic data, etc.

This work aims to develop an educational tool built over educational laboratory equipment, whose simulation and remote access is modular, flexible and scalable. The objectives of this project are:

Also, a remote access through the Internet has been implemented to the equipment. A registered user can identify the system from real data of position and velocity of the drive shaft in open-loop, tune a PID, analyze its behavior using a webcam and the historic data, etc.

This work aims to develop an educational tool built over educational laboratory equipment, whose simulation and remote access is modular, flexible and scalable. The objectives of this project are:

Also, a remote access through the Internet has been implemented to the equipment. A registered user can identify the system from real data of position and velocity of the drive shaft in open-loop, tune a PID, analyze its behavior using a webcam and the historic data, etc.

This work aims to develop an educational tool built over educational laboratory equipment, whose simulation and remote access is modular, flexible and scalable. The objectives of this project are:

Also, a remote access through the Internet has been implemented to the equipment. A registered user can identify the system from real data of position and velocity of the drive shaft in open-loop, tune a PID, analyze its behavior using a webcam and the historic data, etc.

This work aims to develop an educational tool built over educational laboratory equipment, whose simulation and remote access is modular, flexible and scalable. The objectives of this project are:

- To build a set of simple simulation models, using EJS (Easy Java Simulation), which describe each of the Feedback MS-150 modules. They should be directly used by the students and allow teachers to develop practice-related content carried out with the Feedback equipment.

- To create global simulations of assembled models which involve several single-module simulations.

- To develop a set of practices, from low to high complexity, which incorporate the simulations so that students can perform them in sequence, thus strengthening their knowledge about feedback control using electric motors.

- To make this system accessible remotely over the Internet, to provide users with a virtual/remote laboratory for learning control theory.

Fact Sheet

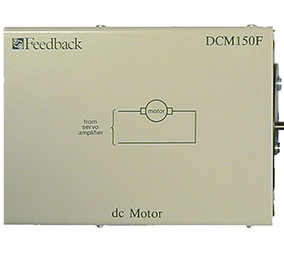

- DCM150F

- Permanently magnetized drive. The drive shaft was extended to mount magnetic brake and inertial wheels.

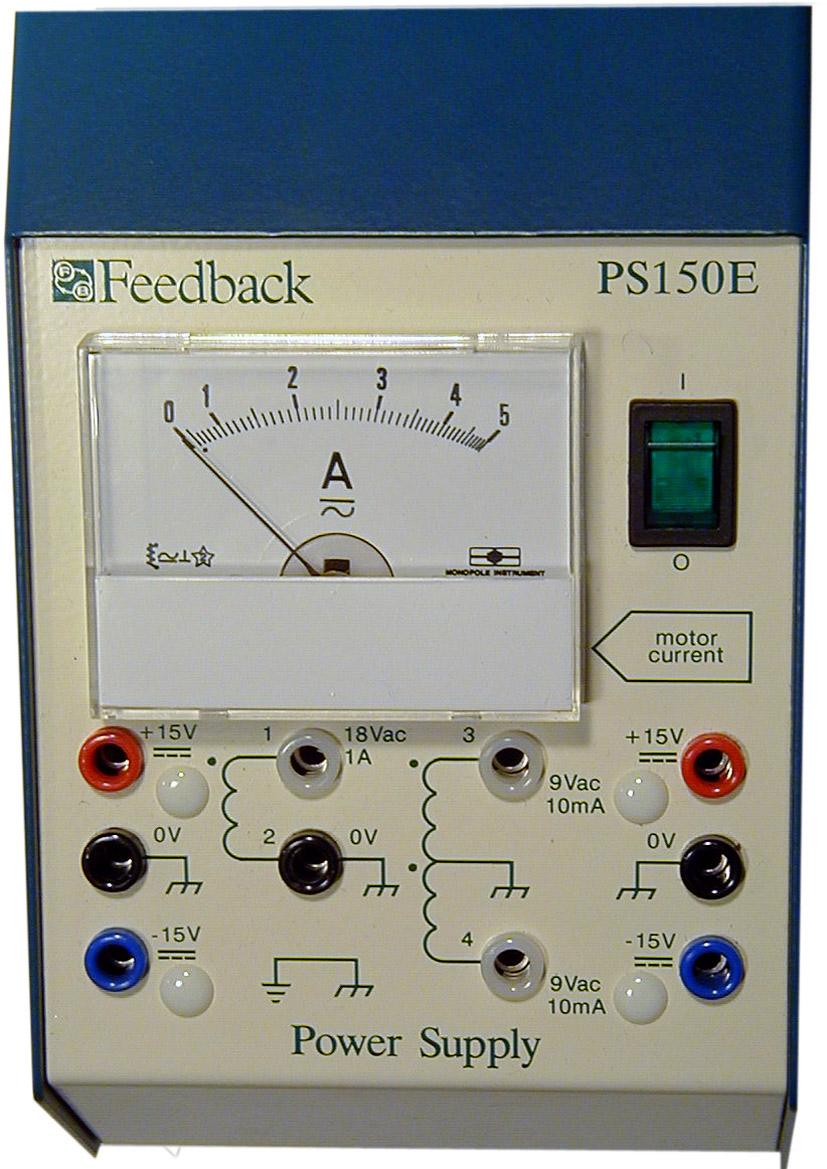

- PS150E

- 220V, 50Hz, 40VA Power supply. 24V d.c 2A output, directly connected to the servo amplifier. Stabilized d.c. ±, 150mA.

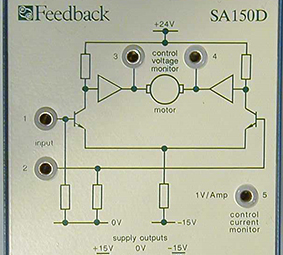

- SA150D

- Servo amplifier that controls the drive power supply.

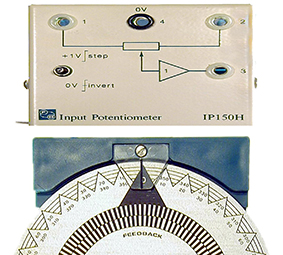

- IP150H

- Potentiometer at the input, with calibrated position indicators.

- OP150K

- Potentiometer at the output, with an extendable shaft to be directly mounted with the tachogenerator unit.

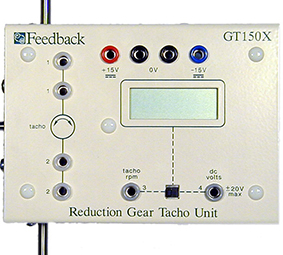

- GT150

- Tachogenerator with a 30/1 reduction system with LED display and d.c. output.

Pictures Gallery

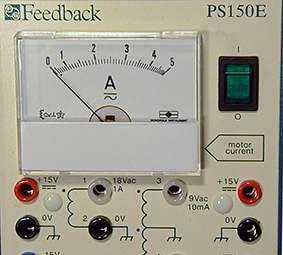

POWER SUPPLY UNIT PS 150 E

This unit provides a continuous stream of 24 volts and 2 amps, through an 8-pin connector to the servo amplifier that controls the motor. It has two sets of terminals whit DC voltages of +15 and -15 volts, 50mA,to supply other units and reference voltages. To avoid overload, the source includes an ammeter and a few protections.

©2022 Remote Laboratory of Automatic Control