Description

A configuration is implemented which allows to control a frequency inverter through a PLC receiving instructions, through the Internet, from a remote interface. The inverter has been configured so that the control of the drive is programmed in the PLC and a Profibus network is used for communication. There is also an Ethernet network between the PLC and the remote interface.

The motor control system consists of two well defined parts: the PLC and the frequency inverter.

A configuration is implemented which allows to control a frequency inverter through a PLC receiving instructions, through the Internet, from a remote interface. The inverter has been configured so that the control of the drive is programmed in the PLC and a Profibus network is used for communication. There is also an Ethernet network between the PLC and the remote interface.

The motor control system consists of two well defined parts: the PLC and the frequency inverter.

- PLC: Communicates with the remote interface through Ethernet and translates the instructions from the interface to the drive via Profibus.

- DRIVE: The drive receives instructions from the PLC through Profibus and actuates the motor to process the operations indicated by the remote interface.

- Start/Stop the motor.

- Change turning direction of the motor.

- Increase/Decrease turning speed of the motor.

- Time selection of the ramp.

- Enable/Disable the injection of continuous current to act as a charge.

- The percentage of continuous current injected (resistive torque applied to the motor).

Fact Sheet

- PLC S7-300

- CP 343-1 MODULE

- SIEMENS VARIATOR MICROMASTER 440

- SIEMENS MOTOR

- PROFIBUS NETWORK

- ETHERNET NETWORK

It consists of a compact CPU with MPI, 24/16 digital I/O, 5/2 analog I/O, 4 high speed counters (60KHz), Profibus DP port and 48 kB of working memory.

Siemens Communication module. Industrial Ethernet connection 10/100 Mbits/s. Auto-sensing. An IP address can be configured remotely to access to the CPU of the PLC. The FTP server can be used to host web pages.

Frequency inverter with a 1024 pulse encoder, a Profibus card module and a card module for the encoder. It has two main control modes, a vector control and a voltage/frequency control.

The motor is built into the drive. It is a Siemens motor with the following characteristics, Nominal Voltage: 230/400 V. Power: 0.37 kW. Turning speed: 1370 r.p.m.

The communication between the PLC and the MM440 is done via a Profibus network at a speed of 1.5 Mbit/s (Vmax: 12 Mbit/s).

The communication between the PLC and the remote user interface is done through an Ethernet network.

Pictures Gallery

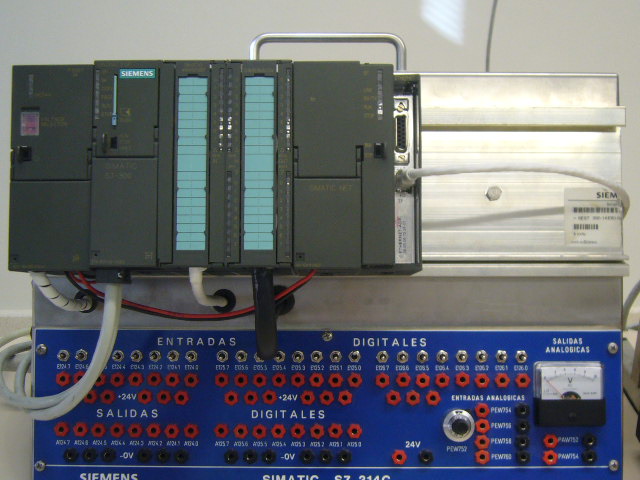

PLC

PLC SIMATIC S7-300. It consists of a compact CPU with MPI, 24/16 digital I/O, 5/2 analog I/O, 4 high speed counters (60 Kz), Profibus DP port and 48 kB of working memory. Additionally, it has a communication module for Ethernet (módulo CP 343-1).

©2022 Remote Laboratory of Automatic Control

©2022 Remote Laboratory of Automatic Control