The Remote Laboratory of Automatic Control (LRA) aims to propose a solution that helps address the main challenge that the European Higher Education Area proposes: creating a Europe of Knowledge. The concept of Europe of Knowledge addresses many different fronts, the SUPPRESS Group (Supervision, Automation and Control) of the University of León, intends, with its Automated Remote Laboratory, to attack the fronts: mobility of knowledge, European cooperation, learning- student, professional commitment in teaching and intensive use of ICT’s.

More specifically, the Research Group aims to demonstrate that its Remote Automation Laboratory achieves the seven basic principles for a good education (AAHE, 1987, Chickering et al., 1996): communication with students, teamwork and collaboration, active learning , evaluation or self-evaluation, time on task, define high expectations and respect the diversity of students.

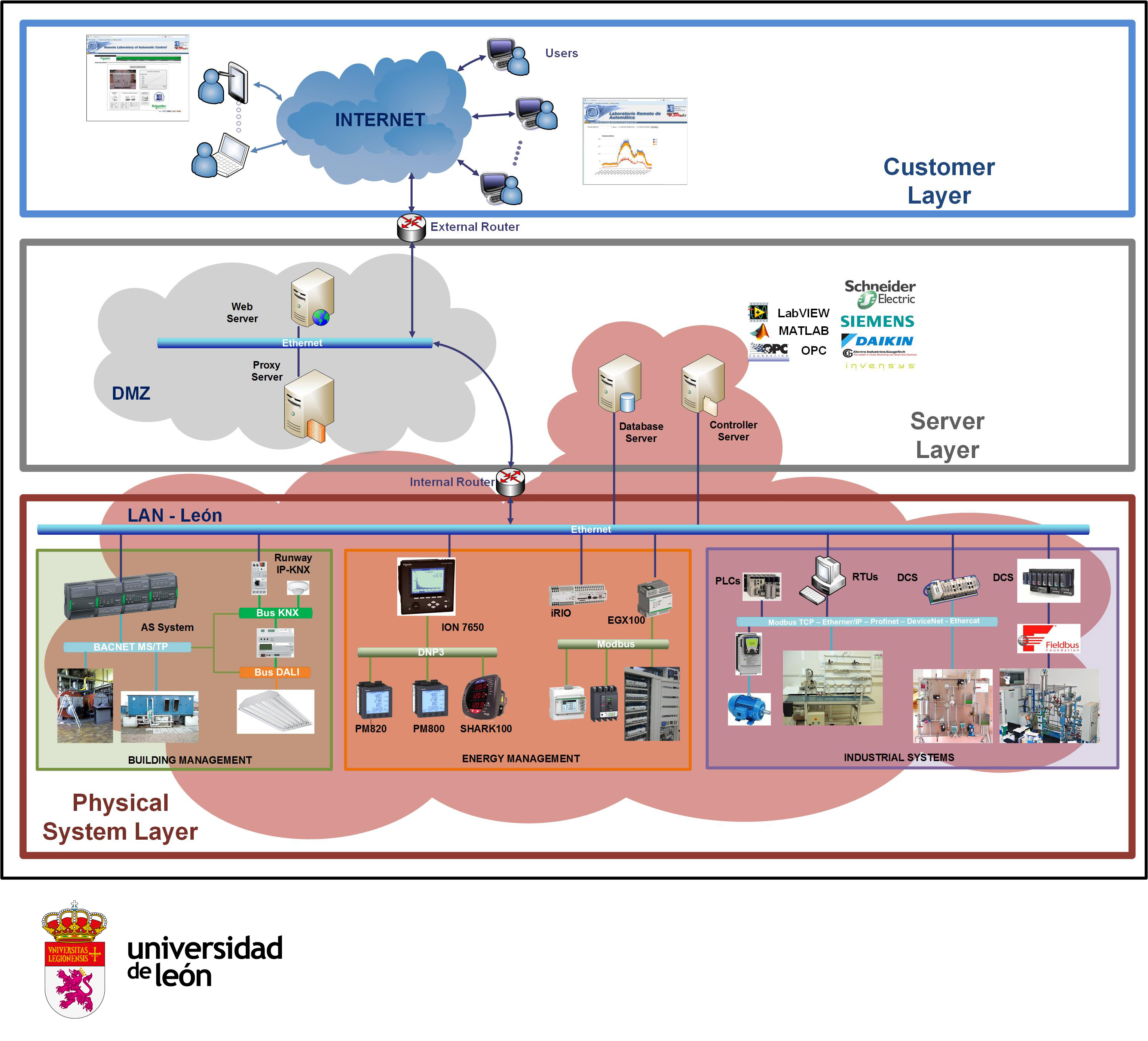

It is designed on a triple layer structure. This structure gives the LRA an open, flexible and non-proprietary nature, in which the processes of development, exploitation, management and incorporation of new equipment are carried out with a systematized and optimized methodology.

The set of systems to which the LRA gives access can be classified into 4 groups:

- Pilot plants and models in which real industrial processes are implemented.

- Technologies for Automation, Control and Supervision.

- Teaching equipment

- Real industrial facilities.

From the point of view of the teaching-learning binomial, the following objectives can be expressed for the LRA:

- To be tool of high value added for the teacher in their theoretical classes by allowing him to illustrate, with realities, concepts of the area of Automatics.

- Clearly define the links between the theoretical contents and their technological implementation, studying them through direct access to real industrial equipment.

- Encourage the shared use of very expensive physical resources and the development of laboratory networks.

- Encourage active and cooperative learning of students.

- Compare the technical characteristics of different and expensive technologies.

From the point of view of the research, the technological platform allows to work in the following research lines:

- Remote supervision of complex industrial processes.

- Development of advanced supervision tools based on techniques of reduction of dimensionality and machine learning.

- Energy supervision of buildings and industrial facilities.

- Intelligent data analysis.

- Supervision and security in critical infrastructures.

- Advanced control.

- Smart grid.